With over 20 years of experience in sales and software, Deepak Raj knew the importance of printing, especially 3D printing. The ex-employee of GE decided to do something in this segment. Although 3D printing was present in the USA for over 2 decades, the technology had not been widely available in India. Raj changed this by launching DF3D or the ‘design factory for 3D printing in 2014.

Just as they started, the Bengaluru-based startup received the opportunity to be a part of TechSparks in 2014 itself. Despite the vision and good start, DF3D did not warm up the Indian market. Six months after inception, they changed their way from B2C into a B2B to generate more revenue. This is when they entered into surgical planning with their new side Osteo3d

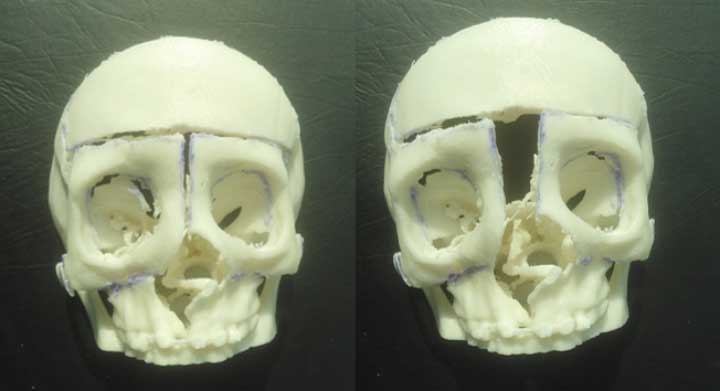

Instead of relying on 2D MRI scans, the doctors could with Osteo3d get a 3D printed life-size model tailored to represent the customer’s problem. Osteo3d helped doctors plan and print 3D models to boost their efficiency in surgeries. This is not only helpful for neurosurgeries but also for maxillofacial surgeries and dentistry work. Amongst their many partners, they have AIIMS.

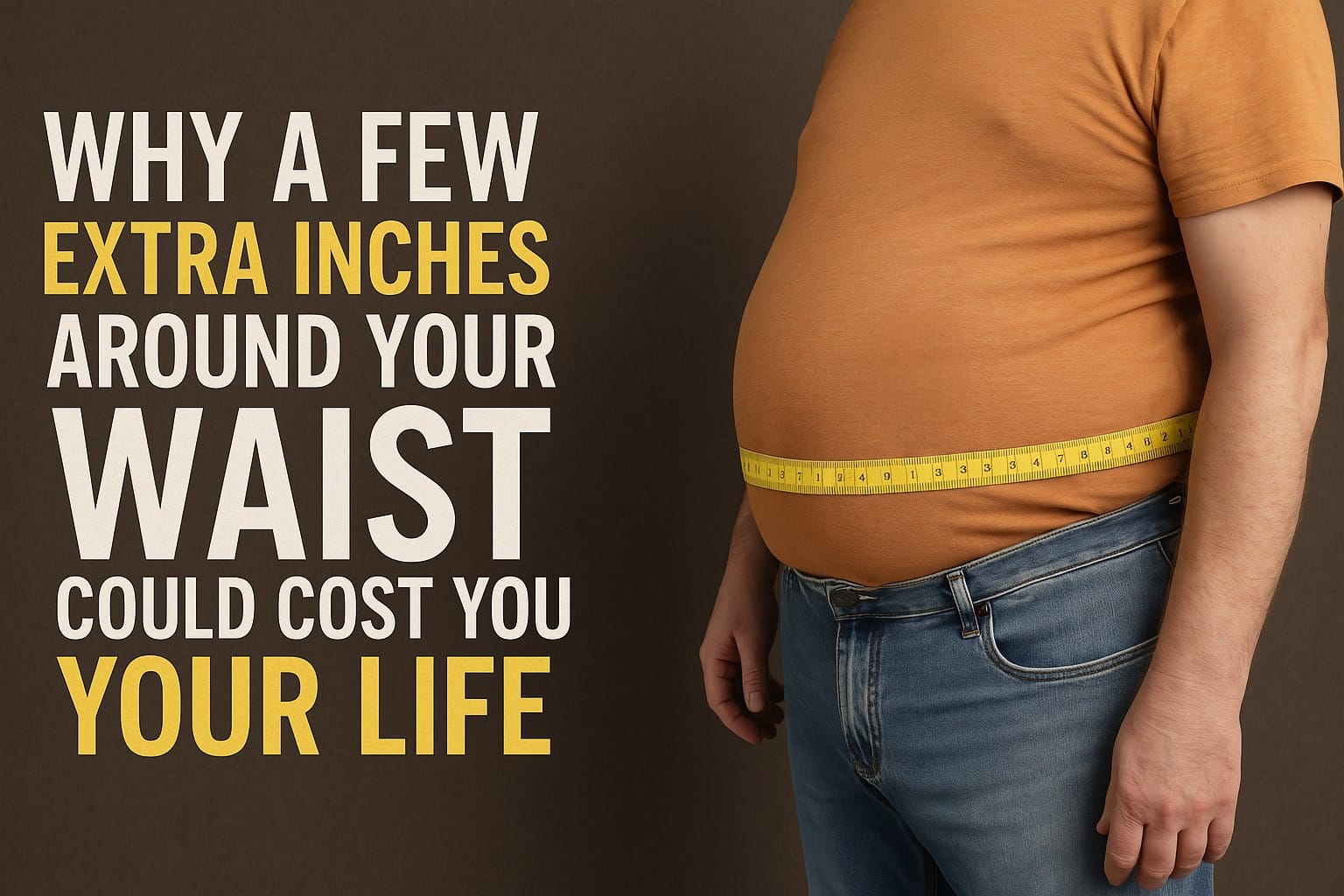

They make customised surgical guides, implants and even cranial helmets. In India 1 in every 2000 kids suffer from skull deformity. By 3D printing customised cranial helmets such kids can avoid developing behavioural disabilities. Where such products cost roughly around Rs 120,000 to import from outside. It could be made by Osteo3d for Rs 30,000.

Osteo3d has been supported and funded by the Union government. In 2015, GOI’s Department of Biotechnology gave Osteo3d a grant of Rs 50 lakhs. A study by 6WResearch says that the Indian 3D printing market will be valued at $79 million in 2021. Works of startups like Osteo3d is not only adding strength to the printing industry but also healthcare.

Will Osteo3d’s 3D solutions help children suffering from skull deformities and aid doctors in their surgeries?

In India 1 in every 2000 kids suffer from skull deformity which can lead to behavioural disabilities. Learn how Osteo3d has a solution for this.

In India 1 in every 2000 kids suffer from skull deformity which can lead to behavioural disabilities. Learn how Osteo3d has a solution for this.

.jpeg)

.jpeg)

.jpg)

.jpg)