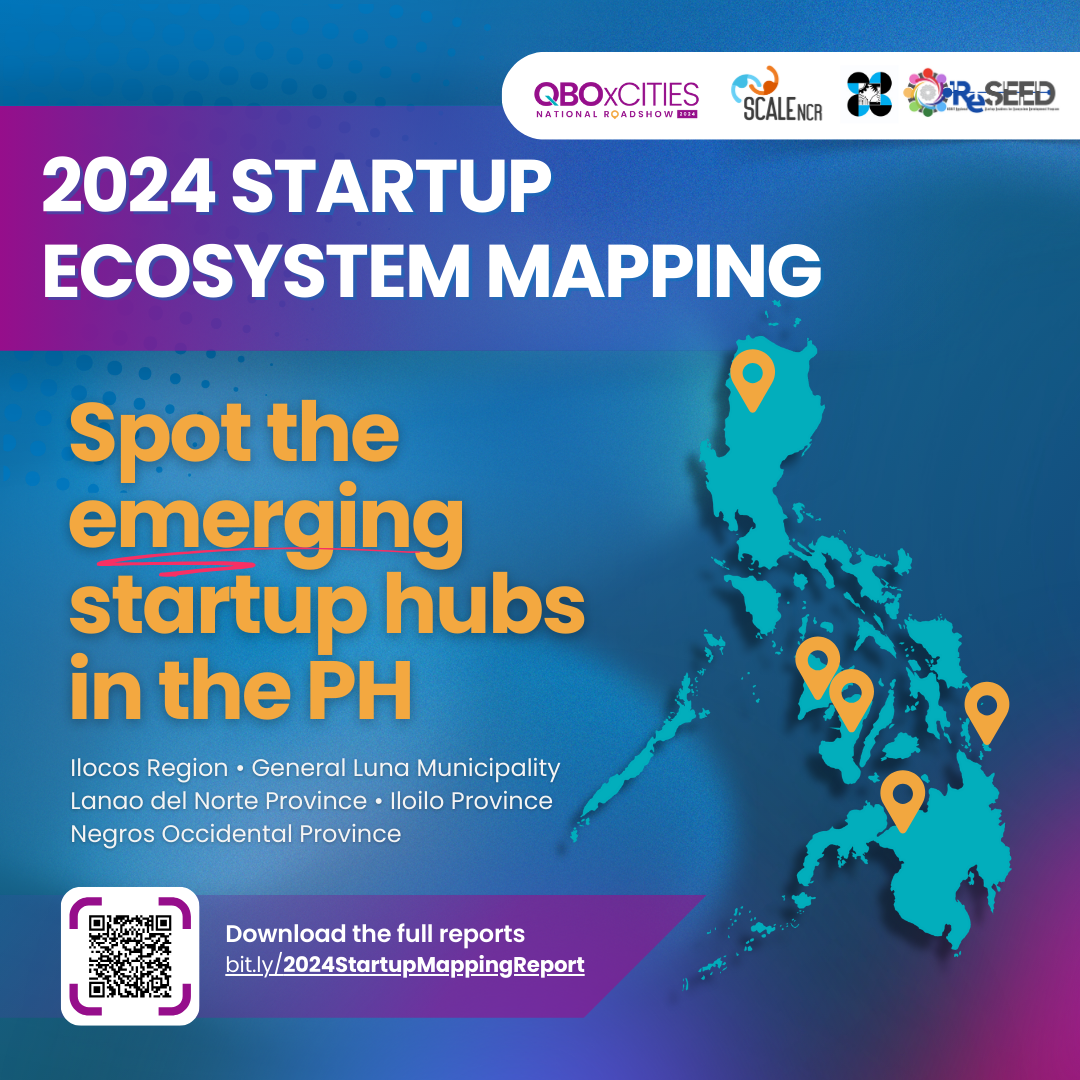

GigaGen Inc., a biotechnology company advancing transformative antibody drugs for infectious diseases, transplant rejection and checkpoint resistant cancers, announced the company has initiated large-scale manufacturing of its first-in-class recombinant hyperimmune drug for COVID-19, GIGA-2050, in collaboration with two partners for Good Manufacturing Practice (GMP), Waisman Biomanufacturing and Goodwin Biotechnology, Inc.

Large scale production of GIGA-2050 will support an Investigational New Drug application (IND) and Phase 1 studies in COVID-19 patients. The GMP product will be subjected to nonclinical GLP toxicology and pharmacokinetics studies in fall 2020 and the company expects to reach the clinic in early 2021.

“Large-scale manufacturing of GIGA-2050 is a crucial milestone for GigaGen for several reasons,” said David Johnson, Ph.D., co-founder and chief executive officer of GigaGen. “It not only puts us on track towards initiation of first-in-human studies for COVID-19 in early 2021 but it demonstrates our ability to execute on novel GMP manufacturing methods for recombinant polyclonal antibody drugs. Polyclonal drugs have been used for years to successfully treat a range of infectious disease and immunodeficiencies, but until now they have only been produced directly from human and animal plasma. Recombinant polyclonal drugs comprise thousands of different clones at very particular ratios, unlike recombinant monoclonal drugs, which deal with one cell clone. To manufacture recombinant polyclonals, we have developed new protocols to optimize production yield, demonstrate consistency across batches and generate a highly pure product. Our success with moving GIGA-2050 to large scale GMP manufacturing in collaboration with our excellent partners paves the way for other promising recombinant hyperimmune in our pipeline in the future.”

GIGA-2050 is a new class of drug designed to provide passive immunity to COVID-19 patients or those at high risk. It can be described as ‘recombinant convalescent serum,’ in that it has the consistency, purity and potency of recombinant antibodies while capturing and enhancing the diversity of anti-coronavirus antibodies observed in convalescent serum. Unlike current recombinant antibody therapies in development for COVID-19 that comprise one or a few antibodies against specific epitopes of the SARS CoV-2, GIGA-2050 comprises more than 12,000 antibodies with strong binding activity against natural SARS CoV-2 variants. Additionally, GIGA-2050 is 100 times more potent than convalescent plasma, which should result in better therapeutic potential. To produce GIGA-2050, GigaGen captured millions-diverse antibody sequences from B cell repertoires of 16 convalescent donors with exceptionally strong antibody responses to COVID-19. Thousands of select libraries have been engineered into mammalian cell line clones to produce the antibody product at large scale.

Karl Pinto, CEO of Goodwin Biotechnology, Inc., commented, “Adding to Goodwin’s years of experience making complex biologic products, this is the first-time manufacturing of a recombinant polyclonal antibody product is being accomplished. For large-scale manufacturing of recombinant monoclonal antibodies, we need to ensure that bioreactors maintain the desired conditions to ensure optimized production of one antibody type. Imagine a bioreactor with thousands of cell line clones producing a thousand different antibody types. To achieve this, we’ve worked closely with the GigaGen team to optimize processes in record time and are honoured to say that, for the first time in history, we are now in the process of producing a pure cGMP product with more than 12,000 anti-coronavirus antibody types, while ensuring batch-to-batch consistency. We are pleased to collaborate with GigaGen on this innovative, game-changing technology.”

Carl Ross, director of Waisman Biomanufacturing, added, “At WB, our mission is to support the development of novel therapeutics and we work collaboratively with companies to find ways to manufacture their groundbreaking drugs. GIGA-2050 is one of the most exciting manufacturing challenges we have encountered and exemplifies our ability to actualize innovative manufacturing techniques. We look forward to continuing to support GigaGen as they carry this potential treatment all the way to the clinic and seeing the impact that GIGA-2050 can have as a treatment for COVID-19 patients.”

GIGA-2050 is a new class of drug designed to provide passive immunity to COVID-19 patients or those at high risk.

GIGA-2050 is a new class of drug designed to provide passive immunity to COVID-19 patients or those at high risk.

.png)

.png)

.jpg)

.jpeg)

.jpeg)

.jpg)

.jpg)